Safe Storage & Shipping with 3–15 Ton Warehouse Beam Cranes

Introduction

Handling long beams in a warehouse comes with its own set of challenges. Unlike smaller materials, beams are heavy, long, and prone to twisting. Even minor mishandling can bend them, damage their ends, or create safety hazards for staff.

Proper storage and shipping are critical. Beams must remain straight, supported, and stable—whether they’re being stacked in the warehouse or loaded onto trucks for delivery. Without the right equipment, mistakes can lead to wasted materials, project delays, and unsafe conditions.

Why Standard Lifting Methods Fall Short

- Hooks or simple slings often allow beams to twist during lifts.

- Uneven weight distribution can damage crane components and the beam itself.

- Workers are exposed to higher risks when handling long beams manually or with improper tools.

The Solution: 3–15 Ton Overhead Cranes with Beam Clamps or Spreaders

Overhead cranes in the 3–15 ton range, equipped with beam clamps or spreaders, are specifically designed for these challenges. They:

- Distribute the load evenly along the beam length.

- Keep beams level during movement.

- Reduce stress on both the crane and the material.

- Allow safe stacking and efficient loading onto trucks.

With the right crane and attachments, warehouse teams can move beams safely, protect materials from damage, and streamline storage and shipping operations. It’s practical, efficient, and makes a noticeable difference in daily workflow.

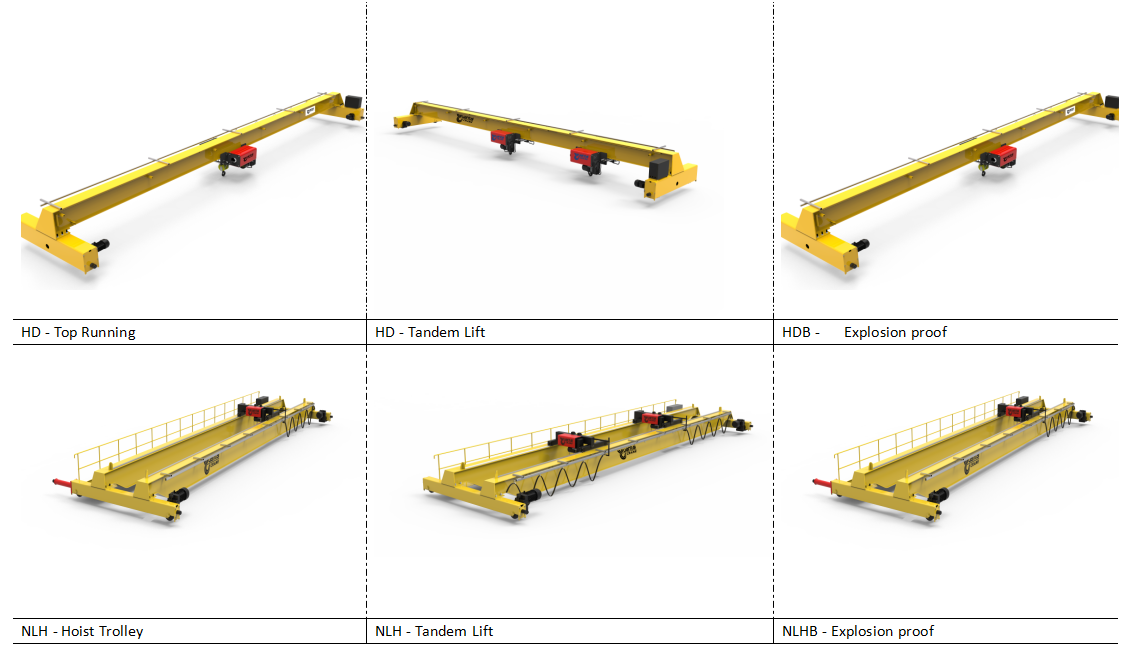

Crane Type and Features

An overhead crane with beam clamps or spreaders is a specialized lifting system designed for long, heavy materials like steel or timber beams. Unlike standard cranes that use a single hook, these cranes use attachments to grip or support the beam along its length. This ensures stability, safety, and even weight distribution during lifting.

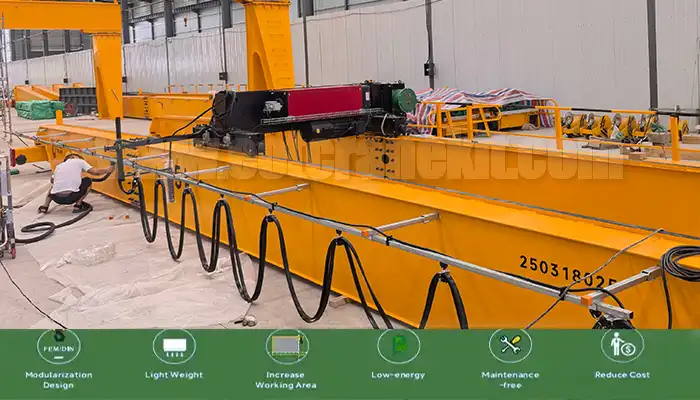

15 ton overhead crane for sale , check our tailored double girder overhead crane with eletromagentic beam for long beam handling

Main Components

- Bridge and Runway: The crane moves along the length of the warehouse on elevated rails.

- Hoist: Lifts the load vertically, available in capacities from 3 to 15 tons.

- Beam Clamps or Spreaders: Attach directly to the beam, holding it securely and keeping it level.

- Trolley: Moves the hoist and attachment horizontally along the bridge.

How Beam Clamps and Spreaders Work

Beam clamps and spreaders are designed to support long materials evenly. Instead of concentrating the weight at a single point, they distribute the load along multiple points of the beam.

- Beam Clamps: Grip the beam ends or edges, preventing twisting or slipping. Ideal for stacking and transporting single beams.

- Spreaders: Attach at multiple points along the beam, often with adjustable lengths, ensuring even lifting for longer or heavier beams.

This load distribution reduces stress on both the crane and the material, keeping beams straight and preventing surface or end damage.

Advantages Over Standard Hooks

Using beam clamps or spreaders provides several practical benefits compared to traditional hook lifts:

- Even Load Distribution: Reduces the risk of bending, twisting, or damaging the beam.

- Enhanced Safety: Fewer chances of the load slipping or falling, protecting both workers and materials.

- Better for Long Beams: Can handle lengths that are difficult or unsafe for standard hooks.

- Efficient Stacking and Shipping: Beams remain level, making stacking and truck loading faster and safer.

Capacity and Range

A 3–15 ton overhead crane covers most warehouse needs when handling long beams. This capacity range allows flexibility for different beam sizes, materials, and operational demands while keeping lifts safe and efficient.

3–15 Ton Lifting Capacity

The lower end of this range is ideal for smaller steel, aluminum, or wooden beams, while the higher end handles heavier steel beams used in construction or industrial projects. This capacity range allows warehouses to handle a variety of materials without needing multiple cranes.

- Small to Medium Operations: Perfect for warehouses where beams are stored, moved, and loaded onto trucks regularly.

- Adjustable for Multiple Loads: The same crane can lift light beams safely while also handling heavier beams when needed.

- Ease of Installation: Cranes in this capacity range are easier to integrate into existing warehouse layouts without major structural changes.

Flexibility for Different Beam Sizes and Materials

Not all beams are the same. Some are long and thin, others short and heavy. A crane with adjustable beam clamps or spreaders can accommodate this variety, ensuring every beam—regardless of size or weight—is lifted safely and efficiently.

- Adjustable spreaders allow for different beam lengths.

- Beam clamps can fit a range of cross-sectional sizes.

- Works for materials like steel, aluminum, timber, and composite beams.

Safety Margin Considerations

When lifting long beams, it's important to account for the actual weight plus a safety margin. Overestimating capacity can strain the crane and increase risk, while underestimating can slow operations.

- Always check the beam's weight and compare it to the crane's rated capacity.

- Consider dynamic factors: movement, wind (for outdoor lifts), and uneven load distribution.

- A recommended safety margin of 10–20% above the beam's weight helps prevent accidents and ensures long-term crane reliability.

Typical Applications

12-meter beams are long and heavy, making safe movement and placement essential. Proper handling ensures efficiency, prevents damage, and maintains safety for operators and materials.

Warehouse Operations

In a warehouse, moving long beams safely is more than just lifting and carrying. Without proper handling, beams can twist, get scratched, or even fall—creating delays and hazards. Overhead cranes with beam clamps or spreaders allow operators to move beams efficiently while keeping them level and protected.

- Transporting Beams Across Storage Areas: Move beams from one aisle to another without bending or twisting.

- Stacking Safely: Place beams on racks or stacks with clamps holding them evenly, preventing end or surface damage.

- Organizing Inventory: Position beams by size, weight, or type quickly and safely for easy access later.

Shipping Preparation

When beams need to leave the warehouse, proper loading is critical. Overhead cranes with spreaders or clamps make it easier to load beams onto trucks, trailers, or containers while minimizing movement that could cause damage.

- Even Placement on Trucks: Keeps beams level to avoid shifting during transport.

- Maximized Stability: Proper alignment prevents tipping or sliding, which protects both the beams and the transport vehicle.

- Quick Turnaround: Efficient crane handling speeds up loading times and reduces labor requirements.

Safety Considerations

Handling long beams safely requires attention to lifting techniques, proper equipment use, and trained operators. Following best practices minimizes accidents and protects both personnel and materials.

Preventing Beam Twisting and End Damage

Long beams are prone to twisting, bending, or end damage if not lifted correctly. Even minor mishandling can ruin expensive steel or timber and create unsafe conditions in the warehouse. Using beam clamps or spreaders correctly is key to keeping every lift safe and controlled.

- Correct Placement of Clamps or Spreaders: Ensure clamps grip the beam edges or ends properly, and spreaders are positioned to support the full length of the beam.

- Check Beam Balance: Make sure the load is evenly distributed before lifting to prevent tilting or sudden shifts.

- Avoid Overloading: Always lift within the crane's rated capacity, considering a safety margin of 10–20%.

Operator Training and Protocols

Even the best crane and attachments are only as safe as the operator. Proper training and adherence to protocols are essential to prevent accidents and material damage.

- Operator Training: Ensure all crane operators understand how to use beam clamps, spreaders, and the hoist safely.

- Pre-Use Equipment Checks: Inspect hooks, clamps, spreaders, hoists, and rails before each lift. Look for wear, cracks, or loose parts.

- Follow Warehouse Protocols: Maintain clear paths, use proper signaling, and communicate with team members during lifts.

Why 3–15 Ton Cranes Fit This Application

Overhead cranes in the 3–15 ton range provide the right balance of lifting capacity, control, and efficiency for handling long beams safely in warehouses.

Protecting Beams During Lifts

Beam clamps and spreaders hold long beams evenly, keeping the load level during lifting and moving. This protects beam surfaces from scratches and ends from bending or crushing.

- Even Weight Distribution: Reduces stress points on both the beam and the crane.

- Prevents Twisting: Maintains straight alignment during transport and stacking.

- Protects Surfaces and Ends: Minimizes the risk of costly material damage.

Suitable for Typical Warehouse Beams

Most warehouse beams—steel, aluminum, or timber—fall within the 3–15 ton lifting range. This makes the cranes versatile enough to handle different beam sizes, weights, and densities without needing multiple cranes.

- Handles beams commonly used in construction and industrial projects.

- Supports both short and long beams with adjustable clamps or spreaders.

- Flexible enough for warehouses with mixed material storage.

Safer, More Efficient Workflow

Using the right crane and attachments reduces damage and improves operational efficiency. Operators can lift, move, and stack beams more confidently, resulting in faster turnaround and a safer work environment.

- Faster loading and unloading onto trucks or storage racks.

- Reduced manual handling, lowering risk of accidents.

- Streamlined workflow allows more lifts per day without compromising safety.

Practical Tips for Buyers

Buying a 3–15 ton overhead crane for handling long beams requires more than just selecting the right capacity. Practical considerations ensure smooth and safe operations.

Verify Crane Reach and Span

Measure your warehouse carefully. The crane's bridge span and trolley travel must reach all areas where beams will be moved to maximize efficiency and avoid workarounds.

- Measure the full width and length of the warehouse.

- Account for racks, shelving, or obstacles that could limit crane movement.

- Ensure the crane's trolley can travel the full bridge span without obstruction.

Confirm Load Capacity

Match the crane's rated lifting capacity to the heaviest beams you plan to handle. Overloading can cause safety issues and shorten equipment life.

- Include a safety margin of 10–20% above your heaviest beam.

- Consider dynamic factors like lifting speed, uneven loads, or simultaneous movement of multiple beams.

- Verify manufacturer specifications and ensure they meet local safety regulations.

Choose the Right Clamps or Spreaders

Using clamps or spreaders designed for the beam's size and profile ensures safe lifting and reduces the risk of surface or end damage.

- Adjustable spreaders are ideal for beams of varying lengths.

- Clamps should fit the beam width securely without deforming the material.

- For repeated handling of specific beam types, custom clamps can improve efficiency and protection.

Regular Maintenance and Inspection

Ongoing maintenance ensures cranes remain safe and efficient. Scheduled inspections prevent unexpected downtime and extend equipment life.

- Inspect hooks, clamps, spreaders, hoists, and rails before each lift.

- Follow manufacturer-recommended maintenance intervals for lubrication, part replacement, and safety checks.

- Train operators to report unusual noises, wear, or movement immediately.

Conclusion

Handling long beams in a warehouse requires more than just a crane—it requires the right combination of capacity, crane type, and lifting accessories. A 3–15 ton overhead crane equipped with beam clamps or spreaders provides the balance of strength, control, and precision needed for safe, efficient operations.

Key Takeaways

- Safe Beam Handling: Properly distributed loads keep beams straight, protect surfaces, and prevent end damage.

- Efficient Storage and Shipping: Cranes allow faster stacking, easy warehouse movement, and secure loading onto trucks.

- Versatile for Warehouse Needs: The 3–15 ton range handles typical beam sizes and densities, reducing the need for multiple lifting systems.

- Reduced Risk and Increased Productivity: Operators can move beams confidently, saving time while maintaining safety.

Investing in the right crane setup is a practical decision that protects both your materials and your team. With careful selection, proper use, and routine maintenance, warehouses can handle long beams safely, streamline operations, and minimize costly damage or delays.